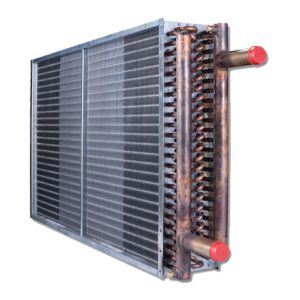

Precision Coils, Engineered for Performance

For custom-engineered coils that optimize your HVAC system’s performance, pick Great American Coil.

As a leading coil manufacturer in the USA, we offer a wide range of HVAC heating and cooling coils for replacement and new construction.

By collaborating with you, we streamline the integration of our coils into your production workflow, ultimately driving down costs and accelerating your time-to-market.

Partner with our coil manufacturing company and experience the Great American Coil difference.

Find The Best

ORIGINAL EQUIPMENT MANUFACTURER’S SUPPLIER (OEM)

We design and provide coils built to OEM specifications for manufacturers across North America that meet or exceed AHRI and UL standards.

Utilizing 3D modeling in our design process, we are able to ensure the heat exchangers built to your specifications fit your air handlers, terminal units, chilled beams or other HVAC units.

With our short lead times and dependable delivery, you can count on us to respond quickly to your needs, minimize your inventory and maximize your cash flow.

Contact us today to see how we can help your business.

Get Custom

New Construction Coils

Designing a coil for new construction is complex. Every component must meet the specific requirements of the project.

Great American Coil simplifies the process. We collaborate with you to design a custom coil that fits your project perfectly.

Let’s discuss your project. We’ll ensure your HVAC system achieves optimal performance with a new custom coil.

Why Pick Our Nationwide HVAC Coil Supplier?

Fast Turnaround Times

We’re known for having some of the fastest turnaround times. We also have a quick-ship program that gets you your coils even faster.

Competitive Pricing

We offer competitive pricing on all our products and services without sacrificing quality.

Industry-Leading Quality

We stay ahead of the curve with advanced technologies to deliver next-gen, efficient coil solutions.

Our HVAC Coil

Quality Assurance

Pressure testing: Each coil is pressure tested with at least 500 PSIG of dry air. We can also perform higher pressure tests if needed for your application.

Dehydration: After pressure testing, coils are dehydrated in an oven to remove any moisture. We use either dry air or nitrogen for this process, depending on the specific application.

This attention to detail ensures our coils arrive ready to perform flawlessly.